In the field of artificial flower manufacturing, the design and production of flower stems are core to achieving both natural aesthetics and practical functionality. Here is the customization Technology and Craftsmanship Analysis of Artificial Flower Stems

I. Stem Design and Mold Development

Customization begins with translating designs into physical forms. After designers complete the drawings, mold carving is used to materialize the design:

-

Machine Tool Carving: Suitable for standardized, symmetrical stem shapes, offering high precision and efficiency.

-

Hand Carving: Ideal for natural curves and complex textures, capturing subtle morphological details.

-

Hybrid Process: Combines the efficiency of machine tools with the detailed adjustments of hand carving to optimally realize the design intent.

After mold completion, a testing and fine-tuning phase is essential to ensure seamless connections and natural stem morphology before trial production.

II. Stem Types and Technical Characteristics

Based on usage scenarios and functional requirements, stems are mainly categorized into two types:

-

Bendable Stems with Internal Iron Wire

-

Core Structure: Internal iron wires of varying thicknesses provide both support and flexibility.

-

Key Craftsmanship: The use of locking ring technology prevents wire penetration or displacement. The number of rings must balance security and aesthetics—excessive rings affect natural appearance and require texture masking or color matching to minimize visual impact.

-

Applications: Wedding arrangements, commercial displays, and other scenarios requiring frequent adjustments.

-

-

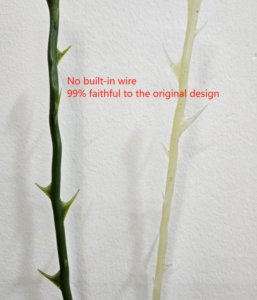

Solid Stems Without Iron Wire

-

Core Advantage: One-piece molding perfectly replicates design details without structural exposure risks.

-

Material Science: Plastic particle formulations (e.g., PVC/PE ratios) are tailored to balance flexibility and strength based on support and elasticity requirements.

-

Applications: High-end home decor and long-term display scenarios with fixed designs.

-

III. Customized Production Process

-

Requirement Analysis: Clarify the client’s specific needs for stem morphology, flexibility, and usage scenarios.

-

Material Selection: Choose iron wire specifications or plastic formulations based on functional requirements.

-

Mold Trial and Testing: Produce samples and validate structural stability.

-

Trial Production: Check batch consistency and adjust工艺 parameters.

-

Mass Production: Strictly control injection molding, assembly, and quality inspection processes.

IV. Why Choose YalzoneMet for Customization?

Although YalzoneMet does not engage directly in production, we leverage years of accumulated supply chain resources and technical integration capabilities to provide one-stop customization solutions.

-

Cross-Factory Collaboration: Break the limitations of single-factory processes by combining multiple technical strengths.

-

Cost Optimization: Secure favorable pricing through order integration and avoid minimum order quantity restrictions when dealing directly with factories.

-

Risk Control: We manage supply chain and quality control, reducing clients’ direct exposure to production issues.

We understand that stems are the “skeleton” of artificial flowers, and their quality directly determines the product’s vitality. YalzoneMet is committed to delivering solutions that combine natural beauty and practical performance with professional craftsmanship and rigorous attention to detail.

YalzoneMet firmly believes that excellent customization lies not in owning factories but in precise resource integration and professional process management. We aim to serve as a technical bridge between you and manufacturers, making artificial flower customization more efficient and reliable.